Heavy lifting control and inspection services

Loading Supervision and Inspection

analysis, audit, cargo, commodity, goods, identification, report, certification, inspection, inspector, product, quality control, sampling, supervision, survey, surveyor, testing, verification, loading, unloading, cargo, goods, product, expertise, expert, independent, Vietnam, China, Asia, Global. email: aimcontrol@hotmail.com

Monday, March 21, 2022

Friday, September 25, 2015

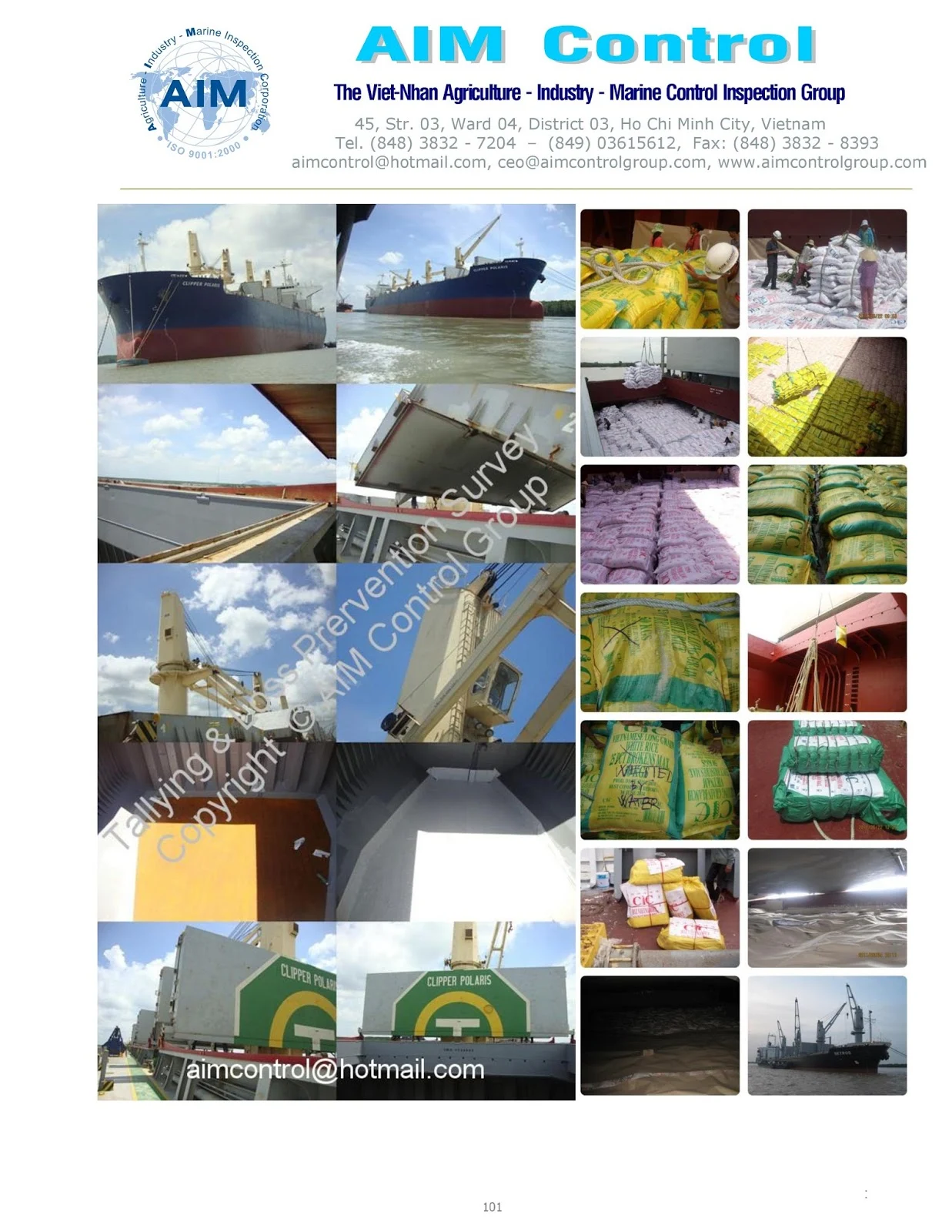

Inspection during loading operation

LOADING SUPERVISION & INSPECTION

Inspection during loading operation

Inspection during loading supervision:

Sub:

AIM’S

Surveyor appointed at any Load port for the job of Draft Survey,

Hatch Inspection, Cargo Tally, Cargo Supervision, Sampling and analysis,

Sealing of holds etc. for

cargo in bulk (or in bags)

AIM’S

Surveyor appointed at any Load port for the job of Draft Survey,

Hatch Inspection, Cargo Tally, Cargo Supervision, Sampling and analysis,

Sealing of holds etc. for

cargo in bulk (or in bags)

Note:

AIM surveyors, supervisors, tally men and consultant have experience

of successful completion of similar

work during over 20 years follows:

of successful completion of similar

work during over 20 years follows:

For Cargo in Bulk:

The Inspection AIM is always ensure that the draft survey is

performed diligently with accurate recordings of all the variables such as

draft, densities, as well as fresh water, ballast, bilge and fuel oil etc. The

Inspection AIM is ensure to provide to AIM’s Client the vessel hydrostatic

tables and vessel sounding hydrostatic table used for calculation of draft

survey.

performed diligently with accurate recordings of all the variables such as

draft, densities, as well as fresh water, ballast, bilge and fuel oil etc. The

Inspection AIM is ensure to provide to AIM’s Client the vessel hydrostatic

tables and vessel sounding hydrostatic table used for calculation of draft

survey.

In case of loss to AIM’s client on account of abnormal shortfall

of material received at disport, suitable penalty and legal action shall be

taken against the Inspection AIM.

of material received at disport, suitable penalty and legal action shall be

taken against the Inspection AIM.

For Cargo in Bags:

The Inspection AIM is always ensure that the Tallying of

quantity and supervision are performed

diligently with accurate recordings of all the variables such as tally sheet,

daily tally report, final tally report, counter-signature, packing list, B/L,

Invoice, Number of barges, lighters, random weighing reports, moisture /

humidity measurement report, packing and marking report, loading supervision

records, loading final survey report etc. The Inspection AIM is ensure to

provide to AIM’s Client the all of data and document used for inspection during

loading operation.

quantity and supervision are performed

diligently with accurate recordings of all the variables such as tally sheet,

daily tally report, final tally report, counter-signature, packing list, B/L,

Invoice, Number of barges, lighters, random weighing reports, moisture /

humidity measurement report, packing and marking report, loading supervision

records, loading final survey report etc. The Inspection AIM is ensure to

provide to AIM’s Client the all of data and document used for inspection during

loading operation.

In case of loss to AIM’s client on account of abnormal shortfall

of material received at disport, suitable penalty and legal action shall be

taken against the Inspection AIM.

of material received at disport, suitable penalty and legal action shall be

taken against the Inspection AIM.

In

past years and nowadays, Client always wishes to appoint AIM’s Surveyor at any

Port for carrying out Inspection during loading

past years and nowadays, Client always wishes to appoint AIM’s Surveyor at any

Port for carrying out Inspection during loading

supervision

as under:

as under:

Loading Port and Parcel Size: Load Ports: Any Port

Shipment / Parcel Size: as per P.O

(or sale contract), per vessel, per shipment

(or sale contract), per vessel, per shipment

Loading Period: will be

confirmed via Ship’s Agent / Master and / or Concerned parties (before loading

operation until to completed loading & securing for vessel departure

confirmed via Ship’s Agent / Master and / or Concerned parties (before loading

operation until to completed loading & securing for vessel departure

Rate of inspection:

AIM is requested to quote AIM’s most competitive one composite

rate on

rate on

All-inclusive basis in the following format only.

Sr. No

|

PRICE / FEE

|

Name of Port

|

Scope of Work

|

||

1

|

Quote AIM’s all inclusive rate for jobs mentioned below at III A SR. No. 1

to 10 in Scope of Work. |

Rate US $ PER MT

|

Rates offered in any other

format or currency shall not be accepted.

The quotations received in different form will not be considered for

evaluation.

format or currency shall not be accepted.

The quotations received in different form will not be considered for

evaluation.

Scope of Work:

INSPECTION DURING LOADING OPERATION:

Inspection of cargo.

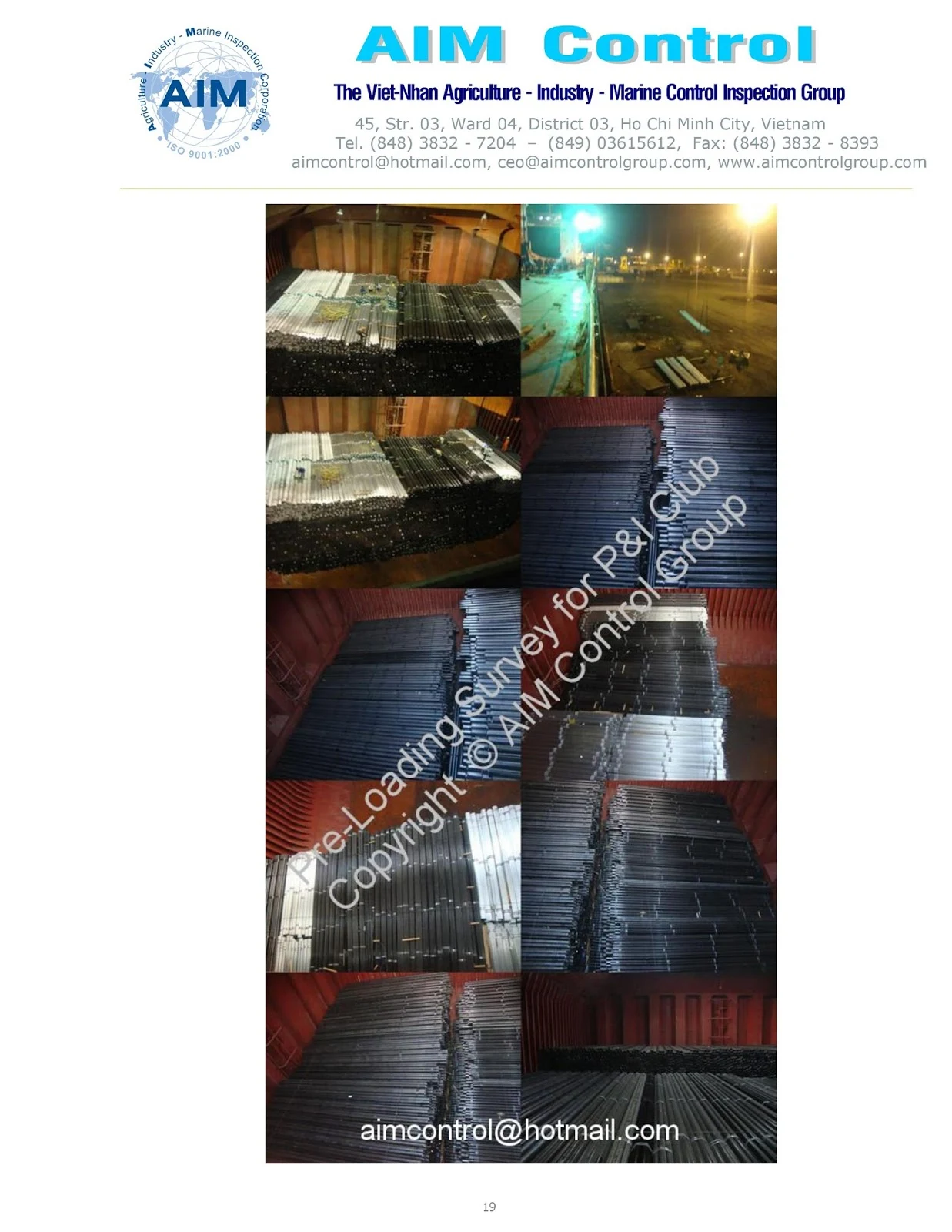

1. Pre-loading survey: inspection of

cargo condition while it on yard / berth of port

cargo condition while it on yard / berth of port

2. Inspection of vessel hatches / holds and hatch covers and issue of hatch / hold inspection Certificate. Also give us information about cargo carried by vessel in its earlier

voyage.

voyage.

3. Preparation of Statement of Facts / Events from the time of vessel’s

arrival at Load port till

the sailing of the

vessel which shall be duly

signed by Master

of the vessel and / or his agent.

arrival at Load port till

the sailing of the

vessel which shall be duly

signed by Master

of the vessel and / or his agent.

4. Conduct initial & final draft survey in association with Master

of the vessel to ascertain the

quantity loaded in the vessel and issue the weighment certificate / Draft Survey Report. The Draft Survey has to be carried out by qualified and competent / experienced surveyor. The Draft

Survey report shall consist of following:

of the vessel to ascertain the

quantity loaded in the vessel and issue the weighment certificate / Draft Survey Report. The Draft Survey has to be carried out by qualified and competent / experienced surveyor. The Draft

Survey report shall consist of following:

·

Density of sea water at

load port

Density of sea water at

load port

·

Stability tables (hydro-static) of the vessel

Stability tables (hydro-static) of the vessel

·

Sounding of all tanks

available on the vessel

Sounding of all tanks

available on the vessel

·

Details / particulars affecting

the Draft Survey results

Details / particulars affecting

the Draft Survey results

·

Facts & figures

of consumables / deductions on the vessel at Initial &

Final Survey

Facts & figures

of consumables / deductions on the vessel at Initial &

Final Survey

·

Trim to be applied for ascertaining quantity of Ballast and fresh water

Trim to be applied for ascertaining quantity of Ballast and fresh water

5.

Conduct tally of quantity and supervision / survey in association with Master

of the vessel to ascertain the

quantity loaded in the vessel and issue the weighment certificate

/ Quantity Final Report and list of defect / damages found out during loading

operation to consult to Master before signature on Bill of lading. The tally of

quantity has to be carried out by qualified and competent / experienced tally-men and chief of tally.

Conduct tally of quantity and supervision / survey in association with Master

of the vessel to ascertain the

quantity loaded in the vessel and issue the weighment certificate

/ Quantity Final Report and list of defect / damages found out during loading

operation to consult to Master before signature on Bill of lading. The tally of

quantity has to be carried out by qualified and competent / experienced tally-men and chief of tally.

6. Sampling & Analysis (including sieve analysis)

Carry out sampling and prepare Composite Samples in presence of

supplier’s representative.

supplier’s representative.

The representative composite sample shall be drawn in the customary

manner during loading operations in presence of supplier’s representative. A certificate

of sampling detailing destination of the samples

shall be made out and signed by AIM and supplier’s representative

to the sampling process.

manner during loading operations in presence of supplier’s representative. A certificate

of sampling detailing destination of the samples

shall be made out and signed by AIM and supplier’s representative

to the sampling process.

The analysis is to be carried out of the following constituents:

AIM Lab. shall carry out the analysis of the various constituents

detailed under

detailed under

Example for cargo are DAP

Di-Ammonium Phosphate (DAP) (Granular)

|

|

Total

Nitrogen |

% by weight

on dry Basis |

Nitrogen

as Ammonical Nitrogen |

% by weight

on dry Basis |

Nitrogen in the form of Urea

|

% by weight

on dry Basis |

Total P2O5

|

% by weight

on dry Basis |

Water

soluble P2O5 |

% by weight

on dry Basis |

Moisture

|

% by weight

|

Particle Size

|

% should pass through

4 mm IS sieve and

should

be retained on 1 mm IS sieve.

Below 1 mm size should

not be more than % |

Analysis of Composite Sample is to be carried out in AIM’s own lab and

if AIM’s own laboratory is not available, then the Analysis must be carried out

at independent laboratory in presence of AIM’s authorized lab-chemist owning

the responsibility of Analysis results. AIM have to give the name of Laboratory

where the analysis is done if the same is not done in AIM’s own laboratory.

if AIM’s own laboratory is not available, then the Analysis must be carried out

at independent laboratory in presence of AIM’s authorized lab-chemist owning

the responsibility of Analysis results. AIM have to give the name of Laboratory

where the analysis is done if the same is not done in AIM’s own laboratory.

The time allowed for Submission of Analysis results is 5 days from the

day vessel sailed from load port (or date of sampling).

day vessel sailed from load port (or date of sampling).

Samples drawn during loading operation shall be sealed, duly signed by

AIM and Supplier’s representative and shall be sent to following:

AIM and Supplier’s representative and shall be sent to following:

·

Three sealed samples shall be sent to AIM’S CLIENT with

the Master of the vessel for delivery to AIM’S CLIENT’s nominees at port of

discharge,

Three sealed samples shall be sent to AIM’S CLIENT with

the Master of the vessel for delivery to AIM’S CLIENT’s nominees at port of

discharge,

·

Two sealed samples to be retained by AIM

Two sealed samples to be retained by AIM

·

Two sealed samples to be given to suppliers.

Two sealed samples to be given to suppliers.

·

Two sealed samples to be given to ship-owner

Two sealed samples to be given to ship-owner

Be confirmed AIM has AIM’s own laboratory to carry out the required

analysis of given constituents at any country.

analysis of given constituents at any country.

7. Supervision of cargo throughout loading

operation:

operation:

·

Consulting and meeting with Cargo Chief Office, Loading Master and Port

Capt. to expose stowage plan

Consulting and meeting with Cargo Chief Office, Loading Master and Port

Capt. to expose stowage plan

·

Meeting with supplier’s authority, foreman, Cargo Chief Office and

concerned parties who also activities during loading operation.

Meeting with supplier’s authority, foreman, Cargo Chief Office and

concerned parties who also activities during loading operation.

·

Inspection of cargo before loading

Inspection of cargo before loading

·

Inspection of cargo during loading

Inspection of cargo during loading

·

Inspection of lashing and securing after loading

Inspection of lashing and securing after loading

·

Inspection report and certificate

Inspection report and certificate

8. Hold

& hatch sealing:

& hatch sealing:

AIM is ensure and certify that all hatches

are properly sealed

at load port at the time of sailing of vessel from load port

and give certificate of hatch sealing with seal numbers for

cross verification at discharge Port of the same.

are properly sealed

at load port at the time of sailing of vessel from load port

and give certificate of hatch sealing with seal numbers for

cross verification at discharge Port of the same.

9. Photos

& Reports:

& Reports:

AIM is ensure to take all of photos on all of inspection

actions of loading operation and make reports on any defects, damages, loss and

/or unusual.

actions of loading operation and make reports on any defects, damages, loss and

/or unusual.

10. Submission of data documents:

AIM will submit

one set of all the reports to the Supplier

at Load port immediately on completion of loading to enable them to prepare Invoice

/ Bill of Lading etc.

one set of all the reports to the Supplier

at Load port immediately on completion of loading to enable them to prepare Invoice

/ Bill of Lading etc.

AIM should submit the following documents to AIM’S

Client immediately on completion of job by e-mail.

Client immediately on completion of job by e-mail.

A) Statement of Facts. B) Detailed Initial/Final draft survey report.

B) Weighment Certificate. D)

Sample report and Analysis Certificate.

Sample report and Analysis Certificate.

C) Hold Inspection Certificate. F) Joint Sampling Certificate.

D) Stowage Plan. H)

The daily loading report to be sent on e-mail.

The daily loading report to be sent on e-mail.

I) Hatch sealing

certificate with Seal Number

of Hatches

certificate with Seal Number

of Hatches

j) Vessels hydrostatic table, Stability Table

and vessels calibrated

tank sounding table.

and vessels calibrated

tank sounding table.

K) The

pre-loading survey report

pre-loading survey report

L) The

daily tally report

daily tally report

M) The

random weighing report

random weighing report

N) The

moisture / humidity report

moisture / humidity report

O) The

reject of damage and shortage report

reject of damage and shortage report

P) The

final tally of quantity report

final tally of quantity report

Q) The

loading operation inspection report

loading operation inspection report

R) all

of shipping document as Master receipt, Packing list, B/L, Stowage of cargo,

fumigation certificate,

of shipping document as Master receipt, Packing list, B/L, Stowage of cargo,

fumigation certificate,

The original reports in triplicate should be sent to AIM’s client if needing, , along with AIM’s invoice.

Declaration:

In case

of award of work order, AIM will give a declaration that AIM will not be

representing any other agency for the subject appointed to AIM by AIM’S Client.

of award of work order, AIM will give a declaration that AIM will not be

representing any other agency for the subject appointed to AIM by AIM’S Client.

Period

of inspection job:

of inspection job:

It will

be shipped on a vessel per voyage, per P.O or per annual.

be shipped on a vessel per voyage, per P.O or per annual.

Payment:

The

payment for the above services will be made within 30 days from the completion

of each job and on receipt of Invoice based on B/L weight as determined by

draft survey or tallying of quantity.

payment for the above services will be made within 30 days from the completion

of each job and on receipt of Invoice based on B/L weight as determined by

draft survey or tallying of quantity.

Thanking AIM,

AIM’s faithfully,

Dr

Capt. Nguyen Te Nhan

Capt. Nguyen Te Nhan

Subscribe to:

Posts (Atom)